The Duty of Foam Control in Enhancing Product Top Quality and Performance

Foam control is an often-overlooked yet vital element in the quest of product high quality and operational performance across varied industries. This conversation will check out the diverse influence of foam on both item stability and manufacturing procedures, raising crucial inquiries concerning the techniques that can be used to maximize foam control.

Comprehending Foam Formation

Foam formation is a complicated sensation that can considerably affect product quality and operational performance across numerous industries. Comprehending these variables is crucial for taking care of foam successfully.

The fluid's thickness and surface tension play critical functions in foam security. Surfactants, for example, can decrease surface area stress, promoting bubble development but also boosting foam stability, which can be troublesome in specific applications. Mechanical anxiety, temperature level fluctuations, and the visibility of pollutants can worsen foam generation, making it necessary to keep track of these elements during manufacturing processes.

Industries such as food and drink, drugs, and chemical production should be specifically watchful concerning foam control. By realizing the hidden mechanisms of foam development, organizations can execute targeted techniques to minimize its results, thereby protecting operational performance and guaranteeing regular product performance.

Influence On Product Top Quality

The visibility of foam can significantly jeopardize item top quality across numerous sectors. In making processes such as food and drink, pharmaceuticals, and cosmetics, excessive foam can bring about irregular item solutions. For example, in food manufacturing, foam might trap air, influencing appearance and flavor, which can eventually modify consumer understanding and complete satisfaction.

Additionally, foam can impede the harmony of paints and layers, causing defects like bubbles and irregular coatings. In pharmaceutical applications, foam can disrupt the exact application of liquid drugs, possibly impacting therapeutic efficiency and person safety and security. These top quality problems not just reduce the end item's charm but can additionally result in pricey recalls and damages to brand reputation.

Furthermore, the presence of foam can make complex quality assurance actions, making it challenging to accomplish precise measurements and constant results. Reliable foam control not just mitigates these dangers however additionally improves general item quality by guaranteeing that formulations fulfill stringent market criteria. By purchasing foam control methods, business can safeguard their products, boost client satisfaction, and keep an one-upmanship in the market.

Operational Obstacles From Foam

Efficient operations in various sectors can be badly interfered with by the existence of foam, which positions multiple challenges throughout manufacturing processes. Foam can hinder blending and reaction times, restraining the effectiveness of chemical processes. In industries such as food and beverage, foam development can bring about imprecise fill degrees, causing product waste and incongruities in packaging.

In settings where health is vital, such as drugs and food processing, foam can complicate cleaning procedures, developing covert storage tanks for contaminants. This not just raises quality issues however additionally can cause conformity problems with governing standards.

Moreover, the emotional effect on drivers can not be overlooked; too much foam can produce a disorderly workplace, resulting in lowered morale and productivity. In recap, resolving the functional difficulties presented by foam is crucial to maintaining effectiveness and product quality in different industries.

Approaches for Efficient Foam Control

How can sectors successfully mitigate the obstacles positioned by foam? Effective foam control strategies are important for boosting product high quality and functional performance.

Along with chemical solutions, process optimization plays a crucial function in foam administration. Industries can analyze and adjust parameters such as blending temperature, stress, and rate to reduce foam generation. Implementing devices alterations, like installing foam-breaking gadgets or adjusting tank style, can even more aid minimize foam levels.

Routine monitoring and evaluation of foam actions within production processes are additionally vital. Using innovative sensing units and analytics can give real-time data, enabling timely treatments and modifications. Staff training is similarly essential; guaranteeing that employees are knowledgeable about foam characteristics and control methods can result in positive foam monitoring.

Situation Research Studies and Industry Applications

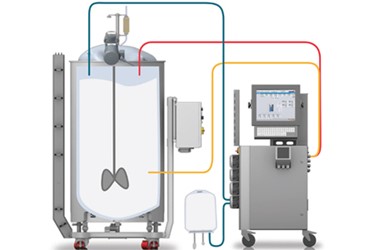

While lots of sectors encounter unique difficulties connected to foam control, case researches expose that customized techniques can dramatically enhance both product quality and operational efficiency. In the pharmaceutical market, as an example, a leading manufacturer executed a customized foam control approach that minimized foam development throughout fermentation processes. This innovation not just boosted yield by 15% however additionally reduced contamination threats, making certain greater item integrity.

In a similar way, in the food and beverage industry, a significant dairy products manufacturer faced too much foam this content during pasteurization - Foam Control. By introducing a specialized antifoam agent, they reduced processing time by 20%, which directly translated to increased throughput and lowered power consumption. The application of foam control gauges ensured consistent product structure and taste, enhancing brand loyalty

In the chemical production industry, an instance research study highlighted the successful application of foam control in wastewater treatment processes. The execution of a real-time tracking system permitted operators to adjust antifoam dosage dynamically, bring about a 30% decrease in chemical usage and enhanced effluent quality.

These instance researches show the diverse applications of foam control across markets, emphasizing its crucial role in boosting item top quality and operational performance.

Final Thought

To conclude, effective foam control is essential Going Here to enhancing product high quality and operational efficiency across different markets. By attending to foam formation, businesses can minimize the negative influence on formulations, texture, and dosing precision. Carrying out targeted foam management methods not only decreases handling delays and waste yet additionally reinforces equipment dependability. Eventually, focusing on foam control adds to boosted efficiency, protecting brand name credibility, and boosting customer contentment, highlighting its relevance in quality assurance within manufacturing procedures.

Foam control is an often-overlooked yet crucial part in the quest of product top quality and operational efficiency across diverse sectors. Staff training is just as important; guaranteeing that employees are knowledgeable about foam dynamics and control strategies can lead to proactive try this foam management.

While several industries encounter distinct challenges connected to foam control, situation studies expose that tailored approaches can dramatically boost both item quality and operational effectiveness (Foam Control). In the pharmaceutical industry, for instance, a leading maker implemented a personalized foam control method that reduced foam formation throughout fermentation procedures.In verdict, reliable foam control is indispensable to enhancing item top quality and functional performance throughout different sectors

Comments on “Just How to Attain Ideal Foam Control for Improved Production Performance”